Servo Power Booster

A protoboard project that allows a separate 9V (or 9-25V) supply to be

used for powering servos driven from a MCU. A controller such as the

Arduino can create the driver signals for a servo. The servo

requires a 5V supply to operate, but a typical development board, such as

a UNO, does not have sufficient overhead in the 5V supply to reliably

provide the servo power. It can be done, but is not recommended,

especially if the servo is operated under some load. Some

servo/motor shields have no provision for a separate power supply, even if

they support a separate supply for attached DC or stepper motors. To

reliably and safely support servos during project development a unit that

can inject a suitable 5V supply into the servo cable is a useful addition

to the workbench.

Note: Although this project is designed for use with servos, it

works just as well for WS2812 (and similar) LED strips. In that case

the signal is the data for the individual LED colour settings rather than

the servo PWM control, but the principal is exactly the same - the ground

and signal are passed straight through, but the 5V supply is boosted to

~2A (referenced to the common ground) by the external voltage input and

the 5V regulator.

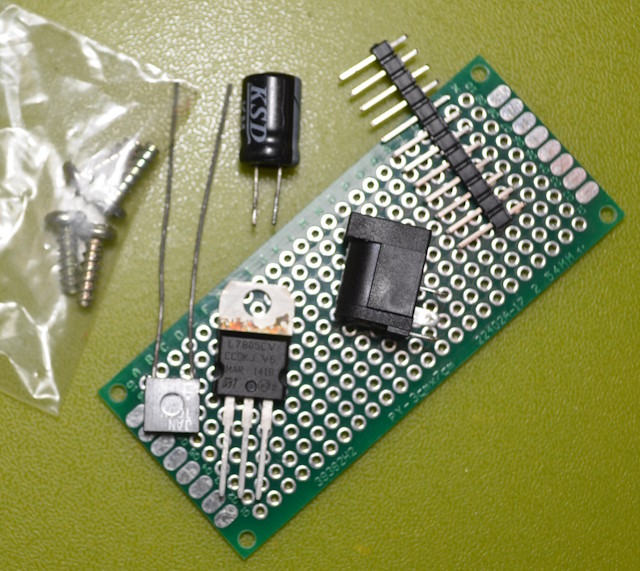

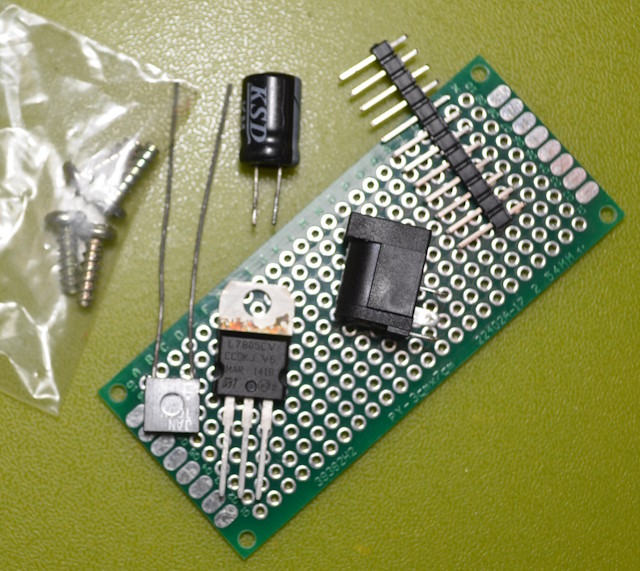

Parts

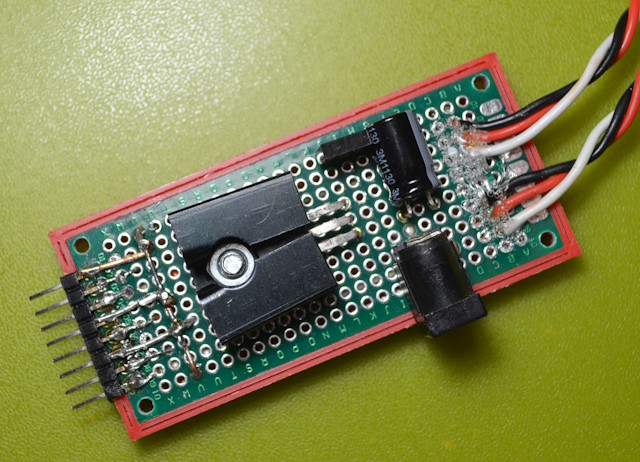

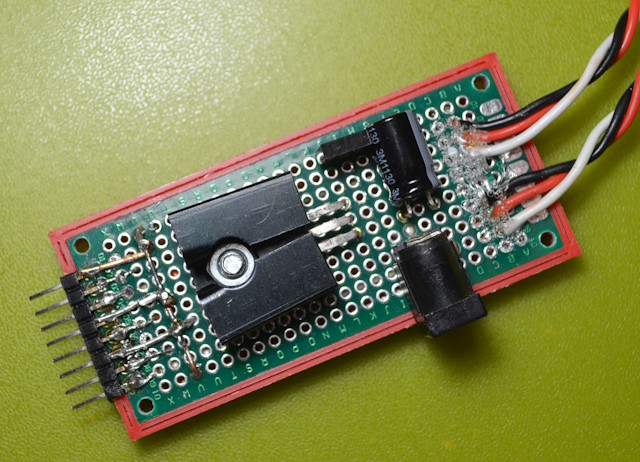

Prototyping

board. Any board of a suitable size can be used. This

one is 70mm x 30mm with holes through the centre section and tabs at each

end. The project uses the tabs for easy connection of the servo

flying leads and pin headers.

Prototyping

board. Any board of a suitable size can be used. This

one is 70mm x 30mm with holes through the centre section and tabs at each

end. The project uses the tabs for easy connection of the servo

flying leads and pin headers.

7805 Linear Regulator (5V). The type is not

critical. In this project the regulator was fitted with a heatsink.

Barrel jack (5.5/2.1mm). This size matches the Arduino

and is commonly available with 9V adapters.

Servo cables.

3-wire servo leads with solder tail and 3-pin 0.1" female conenctor.

Capacitors. 10uF electrolytic and 0.1uF ceramic in this

example. The actual values and types depend a lot on the input

source and the expected usage. The 7805 can operate quite happily

without additional capacitors.

8-pin male header. Only 6 pins are actually

required for the servos, but the extra two can be used to provide a 5V/Gnd

output.

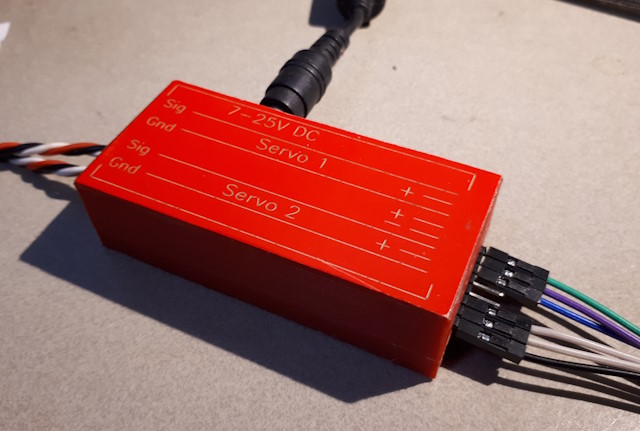

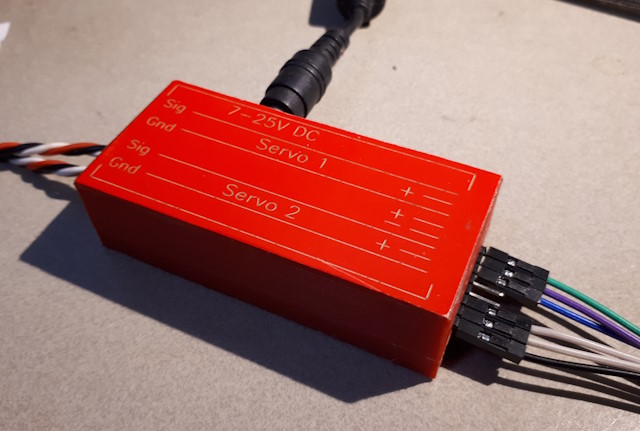

3D-printed case with screws to suit.

Label for case (see below).

The device will be powered from any supply capable of providing 9-25V DC.

The regulator is quoted at up to 2A, but the actual rating will depend on

the heatsink and the duty cycle.

An option not considered for this project is to add a USB connection with

the 5V supply wired straight through to the output pins. If this

upgrade is added then a diode would be required to ensure the USB 5V is

not fed back into the 7805 regulator. A switch would achieve a

similar result without the voltage drop.

Construction

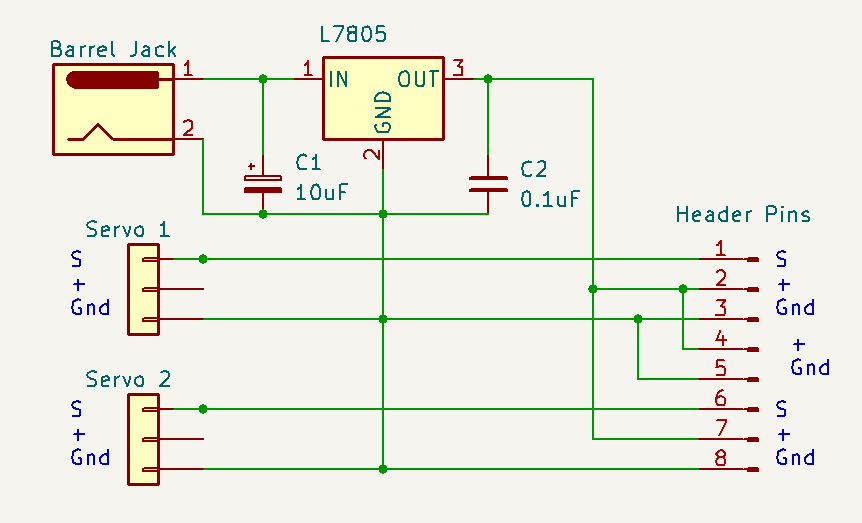

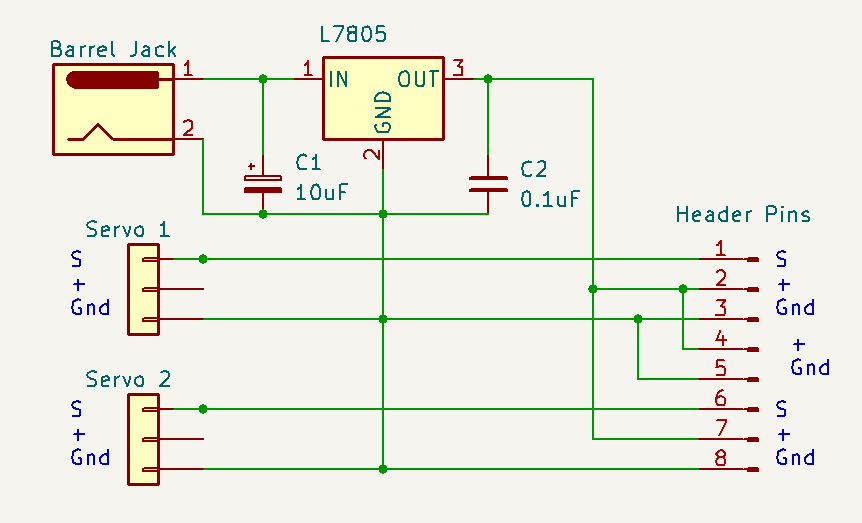

The Circuit layout is quite

simple. The servo signal and ground wires are connected straight

through from the connecting tabs on one end to the header pins at the

other. The servo +5V input is not connected to anything.

The Circuit layout is quite

simple. The servo signal and ground wires are connected straight

through from the connecting tabs on one end to the header pins at the

other. The servo +5V input is not connected to anything.

The barrel jack is wired with a positive pin to the input of the

7805. The 10uF capacitor is wired across the input to ground.

The 7805 ground, the input grounds and the output grounds are all tied

together. The 7805 output is wired to the output +5V headers, with a

0.1uF capacitor to ground.

Additional pins are provided for a spare +5V and Gnd.

This page last updated 18 August 2024

Prototyping

board. Any board of a suitable size can be used. This

one is 70mm x 30mm with holes through the centre section and tabs at each

end. The project uses the tabs for easy connection of the servo

flying leads and pin headers.

Prototyping

board. Any board of a suitable size can be used. This

one is 70mm x 30mm with holes through the centre section and tabs at each

end. The project uses the tabs for easy connection of the servo

flying leads and pin headers. The Circuit layout is quite

simple. The servo signal and ground wires are connected straight

through from the connecting tabs on one end to the header pins at the

other. The servo +5V input is not connected to anything.

The Circuit layout is quite

simple. The servo signal and ground wires are connected straight

through from the connecting tabs on one end to the header pins at the

other. The servo +5V input is not connected to anything.