LiPo Battery Charger Case

This is a small project that simply puts a small LiPo battery charger

module in a case. The charger is used to recharge LiPo batteries

recovered from discarded equipment which are used for powering USB audio

receivers connected to powered speakers at various locations.

However, it involves a mounting method that is suitable for similar

modules that use PC boards that do not provide suitable mounting points,

but which require a secure mounting because they support a USB connector,

which may require some force for insertion and removal of the USB

connector.

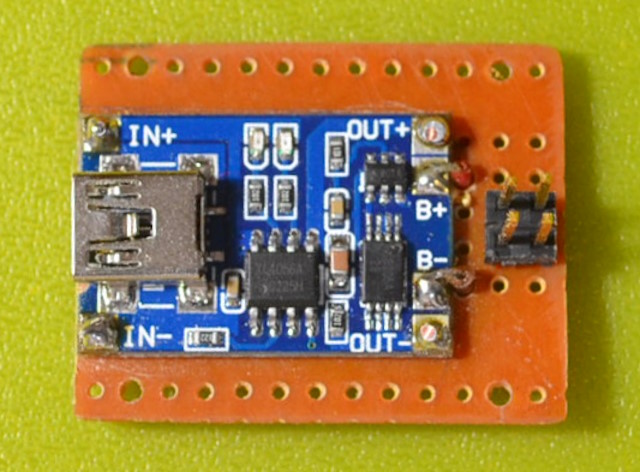

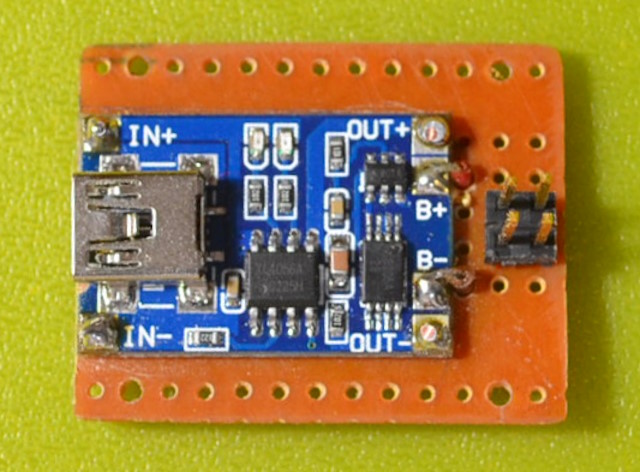

Module

The charger module consists of the USB connector and the components

mounted on a 26mm x 17mm PCB. The input, output and battery charge

connections are at plated-through holes at either end. There are no

mounting holes.

In addition to the lack of mounting holes there is the problem that the

IN+/IN- and OUT+/OUT- pairs are spaced at 14mm, which is not a standard

hole spacing for protoboard. The B+/B- pair is spaced at 8mm, which

is close to, but not quite, 3x0.1" holes. The lengthwise hole spacing is

23mm, which is almost exactly 9x0.1" holes. So the module would fit

the protoboard holes on the long dimension, but not on the short

dimension.

The solution was to:

- Use a protoboard with blank

sections between short horizontal tracks containing (undrilled) vertical

ground planes.

- Stake the IN+ and OUT+ (which

should not be conected) to separate horizontal tracks.

- Drill holes in the ground track

for the IN- and OUT- (which should be connected).

- Disconnect a pair of horizontal

tracks at the output end and mount the headers between them (a

double-row header was used for stability)

- Run wires through holes in the

protoboard from B+ and B- to the underside of the board for the headers.

The stakes are tinned copy wire recovered from a power supply transformer

with the varnish scraped away. The ground track on the copper side

of the protoboard runs midway along the gap between the sets of horizontal

tracks, which works out to exactly match the width of the holes in the

module. The IN- and OUT- are connected on the module, so the

connection through the ground track is just an extra precaution. This

example is intended for stand-alone charging only, so OUT+ and OUT- are

not brought out to any external connector.

B+ and B- are connected by hookup wire brought in through holes from the

underside of the header pins. This is easier than trying to stake

them (considering that they don't line up precisely with any holes) and

then running a connection on the underside.

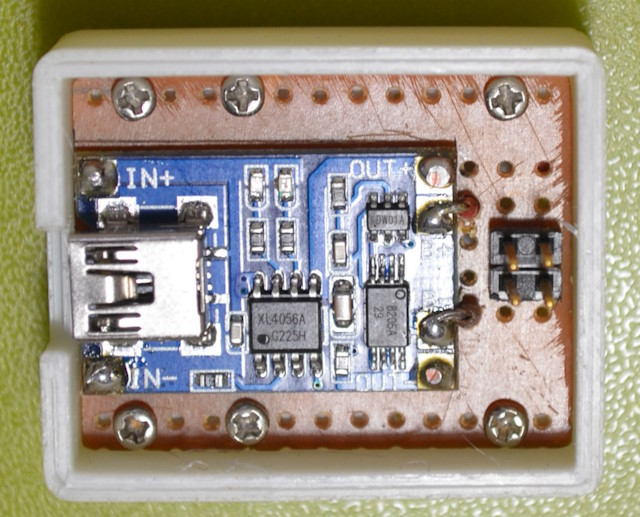

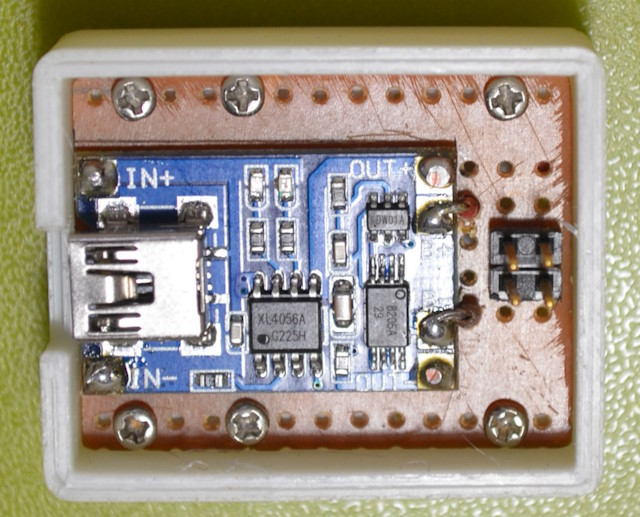

Mounting

Holes

for the mounting screws in the unused vertical rows are drilled out to a

slightly larger size. The case is a simple rectangle to match the

protoboard, with two rails run along the base at the sides for

screws. The case is so small that it was printed with 100% infill

and the screw holes drilled after the board is pressed into the case. The

image shows an additional pair of screws added adjacent to the end of the

USB connector, to ensure a solid mounting at that end.

Holes

for the mounting screws in the unused vertical rows are drilled out to a

slightly larger size. The case is a simple rectangle to match the

protoboard, with two rails run along the base at the sides for

screws. The case is so small that it was printed with 100% infill

and the screw holes drilled after the board is pressed into the case. The

image shows an additional pair of screws added adjacent to the end of the

USB connector, to ensure a solid mounting at that end.

The lid is a simple cap with a cutout to allow access to the header pins.

Note that the cutout for the USB connector seems to suit most micro cables

because they have the housing set back from the insert by the case wall

width of 2mm. This places the cable housing flush with the end of the

case.

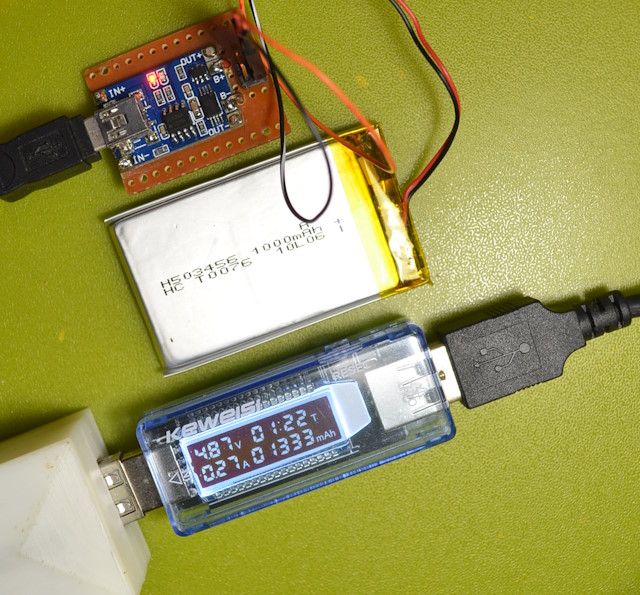

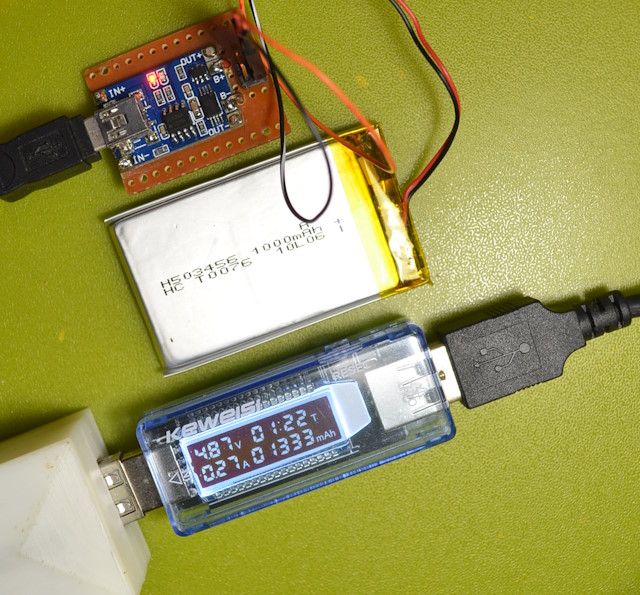

In Use

The

arrangement for using the module for charging a small 1000mAh LiPo

battery.

The

arrangement for using the module for charging a small 1000mAh LiPo

battery.

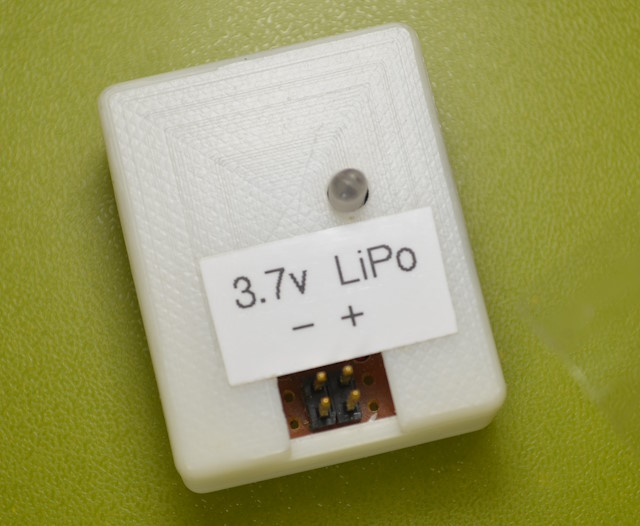

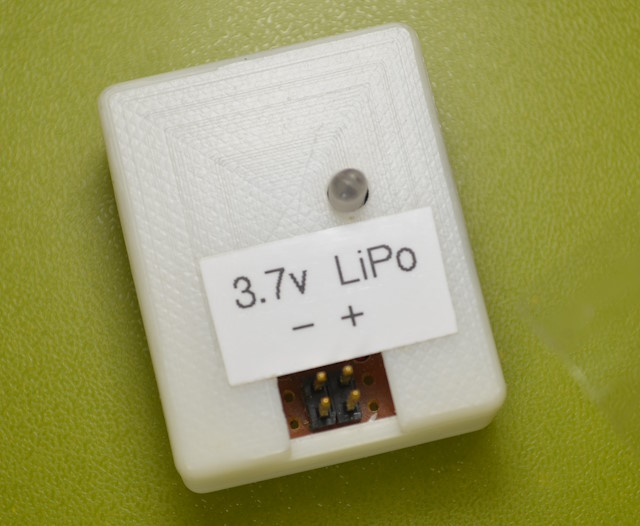

Completed

The completed unit with adhesive label. A short section of

transparent plastic rod (a left over sprue from a model kit) is placed

over the two LEDS and protrudes through a hole in the cap so the light is

visible. The space allowed either side of the header strip is there

because some of the connectors are 3 pins wide (for consistency with

multi-cell batteries that have a balance wire) even though only two are

used.

Holes

for the mounting screws in the unused vertical rows are drilled out to a

slightly larger size. The case is a simple rectangle to match the

protoboard, with two rails run along the base at the sides for

screws. The case is so small that it was printed with 100% infill

and the screw holes drilled after the board is pressed into the case. The

image shows an additional pair of screws added adjacent to the end of the

USB connector, to ensure a solid mounting at that end.

Holes

for the mounting screws in the unused vertical rows are drilled out to a

slightly larger size. The case is a simple rectangle to match the

protoboard, with two rails run along the base at the sides for

screws. The case is so small that it was printed with 100% infill

and the screw holes drilled after the board is pressed into the case. The

image shows an additional pair of screws added adjacent to the end of the

USB connector, to ensure a solid mounting at that end.

The

arrangement for using the module for charging a small 1000mAh LiPo

battery.

The

arrangement for using the module for charging a small 1000mAh LiPo

battery.