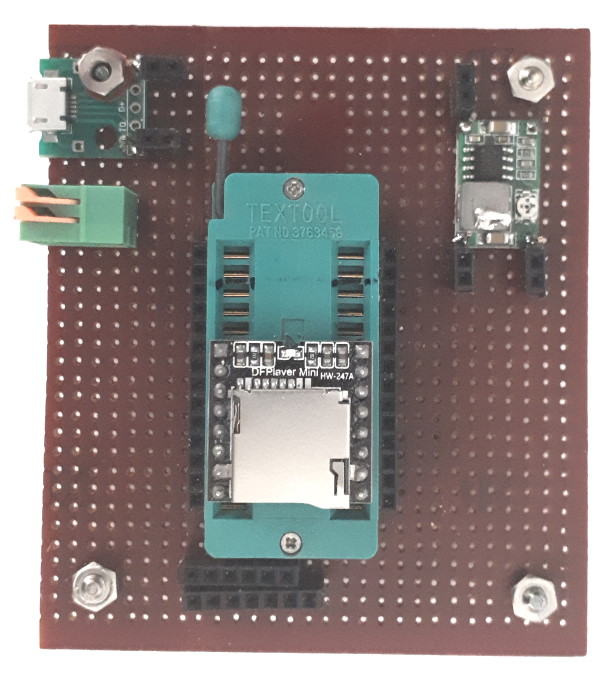

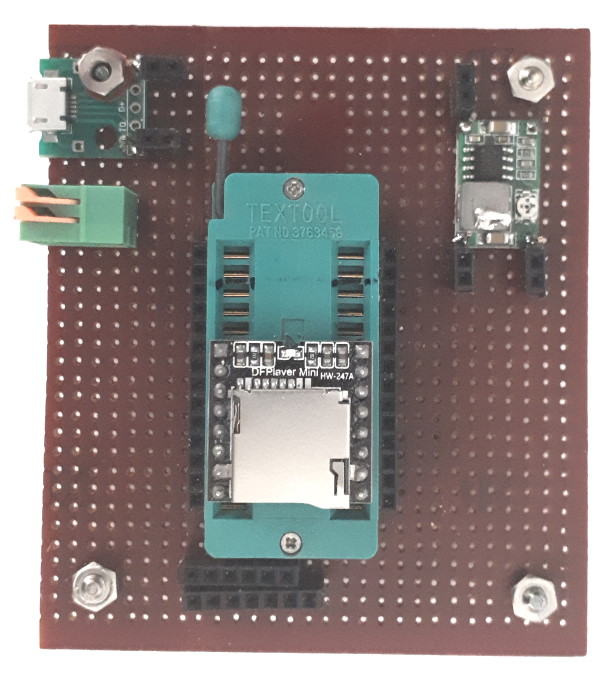

ZIF Breakout Board

This simple project is a little breakout board that uses a ZIF socket to

provide safe access to modules that are wider or longer than the typical

14- or 16-pin DIL ICs. It does much the same job as a

solderless breadboard, but with the difference that the ZIF socket enables

the module to be inserted and removed without any force, and without risk

of breaking the module or its pins. It is particularly suited to

very small modules that tend to use very thin PCB material, such as logic

level converters, LiPO charger modules and step-up or -down voltage

converters. It can also be used with the small 128x64 or

128x32 OLED display modules, which are extremely fragile, and with modules

that are sensitive to poor connections, such as the cheap clone mini MP3

players.

The board has connections for each of the ZIF socket pins, as well as a

small bus for both 5v and Gnd, but of course it could be built to any

configuration.

Parts

ZIF socket. There are many variations available

and the most appropriate can be chosen to match the type of module

typically used. This example uses a 28-pin (2x14) socket that

can accommodate modules with a pin width of 12 to 14mm. Note: this

does not fit an ATMega328 28-pin chip, but versions of the ZIF are

available in that size.

Prototyping board.

Headers: 2 x 14-pin, 2 x 6-pin. Female headers have been used for

consistency with the usual arrangement of MCU prototyping boards.

Mounting feet, or case.

ZIF Socket

The ZIF, or zero insertion force, socket is designed for the

insertion and removal of dual in-line chips and modules, usually in larger

sizes, with zero stress on the chip or its pins. The socket is

opened by raising the lever, so that the chip or module can be inserted

into open connectors. When the lever is closed the connectors

squeeze the pins, creating a secure connection. The chip or module is

removed by raising the lever and opening the connectors.

The ZIF, or zero insertion force, socket is designed for the

insertion and removal of dual in-line chips and modules, usually in larger

sizes, with zero stress on the chip or its pins. The socket is

opened by raising the lever, so that the chip or module can be inserted

into open connectors. When the lever is closed the connectors

squeeze the pins, creating a secure connection. The chip or module is

removed by raising the lever and opening the connectors.

BREADBOARD

Any suitable configuration and size can be used, but

the most convenient will have traces organised in a 'ladder' configuration

where the ZIF solders to rungs on separate rails of the ladder and the

rungs provide connections to adjacent headers. Ensure that the rungs

are far enough apart, or long enough, to allow the headers to be placed

alongside the ZIF without the need to run connections to an adjacent rung.

Any suitable configuration and size can be used, but

the most convenient will have traces organised in a 'ladder' configuration

where the ZIF solders to rungs on separate rails of the ladder and the

rungs provide connections to adjacent headers. Ensure that the rungs

are far enough apart, or long enough, to allow the headers to be placed

alongside the ZIF without the need to run connections to an adjacent rung.

CIRCUIT

Apart from bringing each ZIF pin out to an adjacent header, the

arrangement of the breadboard will depend on the expected usage. In

the example here, the 5v supply is from a two-terminal connector and a

USB-C socket, each connected to a pair of female headers. The USB_C socket

is fastened to the board with stakes, providing one pair of male headers,

as well a a very secure mounting. (The socket board also has extra

holes which can be used for stakes or a wire strap.). There is also a

variable step-down power supply with its own headers for an external

supply. This is also mounted using stakes. Depending on the expected usage

it may be worthwhile to provide fixed 5v and/or 3.3v regulators powered

from a 12v connector. The example provided here will

likely be expanded based on experience with using it with developing

projects.

ASSEMBLY

The

parts are laid out on the prototyping board in a form that uses the

pattern of traces to the best advantage. In this case the only additional

wiring required is for the second 5v connector and the several different

ground points (as the projects it will be used with will not require

floating power supplies). These additional connections can be run across

either the top or bottom (copper) side of the board..

The

parts are laid out on the prototyping board in a form that uses the

pattern of traces to the best advantage. In this case the only additional

wiring required is for the second 5v connector and the several different

ground points (as the projects it will be used with will not require

floating power supplies). These additional connections can be run across

either the top or bottom (copper) side of the board..

If it is necessary to cut the traces then the simplest method is to drill

out an intermediate hole to a larger size from the copper side. This gives

a clean and obvious disconnect. If the trace needs to be

cut between two holes then use a sharp knife and be sure to peel or scrape

away a small segment of track, ensuring that no stray piece of copper can

bridge the gap.

Before soldering components scrub the copper side thoroughly to give a

clean surface so the solder wicks to the copper easily. Prototype boards

vary widely in the quality of the copper coating, but usually require good

cleaning, and often need a light sandpapering to get clean bright copper.

Holes should be drilled in each corner of the board for mounting

stand-offs so that the traces and wiring on the back of the board are

raised from the working surface to eliminate any risk of shorting out on

anything sitting on the workbench. In this example one hole of the

USB socket has been used for a support, to add extra security to the

socket mounting. If metal supports are used be sure to include insulating

washers between the copper traces and the support base. If the USB

socket hole is used for a mount then an insulating washer is also required

for it.

The image shows the board being used with a MP3 player module. For

reasons that are not clear this module is particularly sensitive to poor

connections, so the ZIF socket makes a big difference in reliability and

consistency during prototyping.

The board is also very useful with the Arduino Pro Mini, particularly

when the Pro Mini is configured with only a few pins. Although the

Pro Mini is quite sturdy, it can be damaged when removing from the

solderless breadboard. If it is soldered into the final circuit before the

damage is detected then a lot of effort is involved in removing and

replacing it. The ZIF socket virtually eliminates any risk of

damage.

This page last updated 18 August 2024

The ZIF, or zero insertion force, socket is designed for the

insertion and removal of dual in-line chips and modules, usually in larger

sizes, with zero stress on the chip or its pins. The socket is

opened by raising the lever, so that the chip or module can be inserted

into open connectors. When the lever is closed the connectors

squeeze the pins, creating a secure connection. The chip or module is

removed by raising the lever and opening the connectors.

The ZIF, or zero insertion force, socket is designed for the

insertion and removal of dual in-line chips and modules, usually in larger

sizes, with zero stress on the chip or its pins. The socket is

opened by raising the lever, so that the chip or module can be inserted

into open connectors. When the lever is closed the connectors

squeeze the pins, creating a secure connection. The chip or module is

removed by raising the lever and opening the connectors.

The

parts are laid out on the prototyping board in a form that uses the

pattern of traces to the best advantage. In this case the only additional

wiring required is for the second 5v connector and the several different

ground points (as the projects it will be used with will not require

floating power supplies). These additional connections can be run across

either the top or bottom (copper) side of the board..

The

parts are laid out on the prototyping board in a form that uses the

pattern of traces to the best advantage. In this case the only additional

wiring required is for the second 5v connector and the several different

ground points (as the projects it will be used with will not require

floating power supplies). These additional connections can be run across

either the top or bottom (copper) side of the board..